We provide a range of high-performance structural adhesives specially formulated for composite materials. Our adhesives deliver strong, durable bonds compatible with all common resin systems, ensuring excellent load transfer and resistance to environmental stresses. Trusted by industries including aerospace, automotive, and marine, our products help enhance the strength, reliability, and longevity of your composite components.

Read More

Our advanced mold release systems are built for precision and performance in composite manufacturing. We offer a full suite of internal mold releases (IMR) and external release systems, including a three-step solution: cleaner, sealer, and releaser—engineered to deliver consistent results across production cycles. Formulated for compatibility with both UPR (unsaturated polyester) and epoxy resin systems, our products are ideal for pultrusion, RTM, hand lay-up, vacuum infusion, and compression molding processes. Achieve clean part separation, extended tool life, and flawless surface finishes—cycle after cycle.

Read More

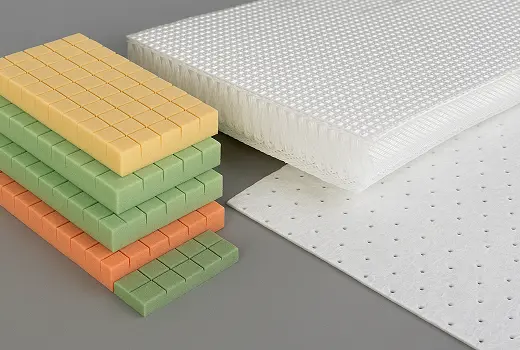

Release Films are engineered to prevent adhesion between the laminate and tooling during vacuum bagging, infusion, or autoclave processes. Available in a range of temperatures, chemistries, and perforation patterns, they support resin flow control and surface finish precision in high-performance composites.

Read More

Our high-performance cutting and polishing compounds are specially formulated for composite surfaces, including gelcoats, epoxy, and carbon fiber finishes. Designed to remove sanding marks, oxidation, and surface imperfections, they restore clarity and achieve a high-gloss, showroom-quality finish. Ideal for marine, automotive, and aerospace composites, these compounds provide fast cutting action with minimal swirl, making them perfect for both production and refinishing applications. Available in multiple grades to suit everything from aggressive material removal to final polishing.

Read More

Our range of high-performance core materials is designed to enhance the strength, durability, and lightweight characteristics of composite structures. Ideal for industries like marine, aerospace, automotive, and construction, our products deliver superior bonding, dimensional stability, and impact resistance. Core Fabrics & Sandwich Mats: Engineered for optimal reinforcement, these fabrics provide excellent drapeability and are ideal for sandwich panel construction, improving stiffness without adding excessive weight. RTM Mats: Specifically designed for Resin Transfer Molding, our RTM mats ensure uniform resin flow and excellent fiber wet-out, resulting in superior composite part quality. PVC & PET Foams: Lightweight and resilient, our PVC and PET foam cores offer exceptional compressive strength and thermal insulation, making them perfect for structural sandwich applications. 3D Fabrics: Advanced woven architectures that provide multidirectional reinforcement and enhanced mechanical properties, ideal for complex composite shapes and high-stress applications. Non-Crimp Fabrics (NCF): Featuring fibers aligned straight and stitched without crimp, NCFs deliver enhanced mechanical properties and improved strength-to-weight ratios, perfect for high-performance composite structures. Experience the perfect balance of performance and versatility with our core materials — engineered to meet the most demanding composite manufacturing needs.

Read More

We offer a specialized range of additives designed to enhance the performance and appearance of composite surfaces across UPR and epoxy resin systems. Pigment Pastes: High-quality, pre-dispersed colorants for uniform color distribution, UV resistance, and excellent stability without affecting curing. UV Stabilizers: Advanced light stabilizers and absorbers to protect composite parts from yellowing, degradation, and surface chalking under prolonged UV exposure. Tack-Free Wax Coatings: Surface wax additives that rise during curing to form a self-sealing film, ensuring a smooth, tack-free finish in applications like gelcoats and topcoats and Resins.

Read More

Contact Us

Address

30 Udyog Kendra2, Ecotech3,

Greater Noida 201306.